From design to product

We care about long-term customer relationships based on professionalism and trust. Thanks to our experience, we actively support clients in the complex process of product creation – from the idea / concept to the final product.

We advise solutions and select production technology so as to meet the customer’s needs.

-

- 01Idea for a new product

-

- 02Analysis and solution

-

- 03Client confirmation

-

- 04Standard sample

-

- 05Prototype acceptance

-

- 06Full production readiness

Technological possibilities and competitive advantage

The production processes are based on four modern technologies that can be implemented on 17 independent production lines. We are able to fulfill orders for both large and small production batches, while offering the highest quality and high technical parameters of products.

- own research and development department

- own laboratory

- own construction department

- own transport

- four independent production technologies

- innovative materials

- own models production taking part on CNC machines

- own production of forms with the necessary fittings

- modern and automated machine park

- after-sales service

- fully automated dosing of raw materials from manufacturer's packaging

- 600μ - 800μ gel coat resistant to scratches and UV

-

seasoning and post-curing of products enabling the production of forms with a 10 mm wall cross-section

- logistic and warehouse support

Materials

To meet customer requirements, we offer our products in four independent technologies based on the highest quality materials. We have created environmentally friendly materials that are also very resistant to chemical substances and mechanical damage.

Sanitary acrylic

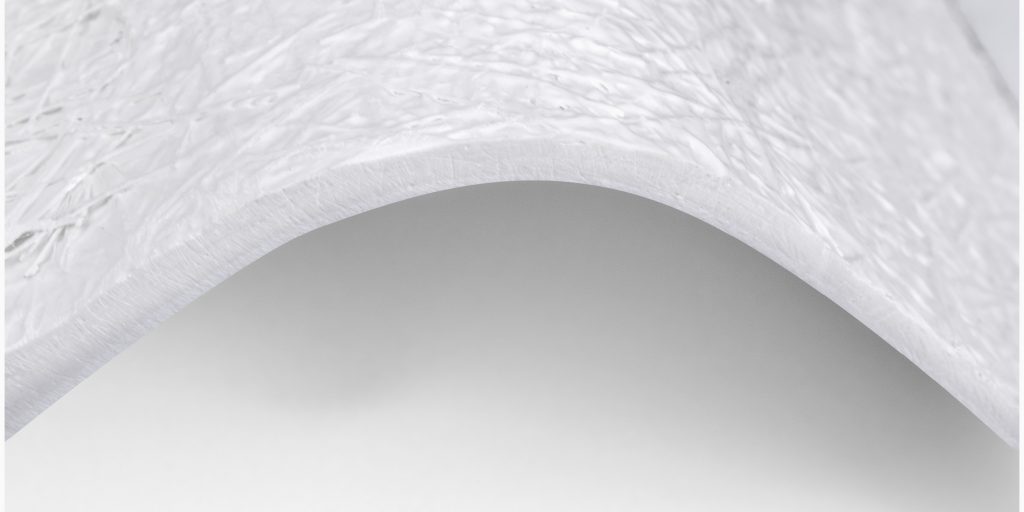

The material is a combination of a thermoformed plate and a mineral composite reinforced by a glass fibre. The use of boards on the base of methyl methacrylate allows forming any shape of the product while maintaining high strength parameters.

It is a material which combines convenience, functionality and a large range of arrangement options.

Benefits

- light material

- dimensional freedom

- possibility of using hydromassage

- thermoplasticity, and thus the ability to obtain any shape from the forms

- hardness and surface strength as well as scratch resistance

- acrylic maintains a constant water temperature longer

- pleasure of use due to the smooth and warm to touch surface

- easy to keep clean, thanks to the smooth, non-porous surface, resistant to contact with domestic cleaning agents

- the ability to repair surface damage

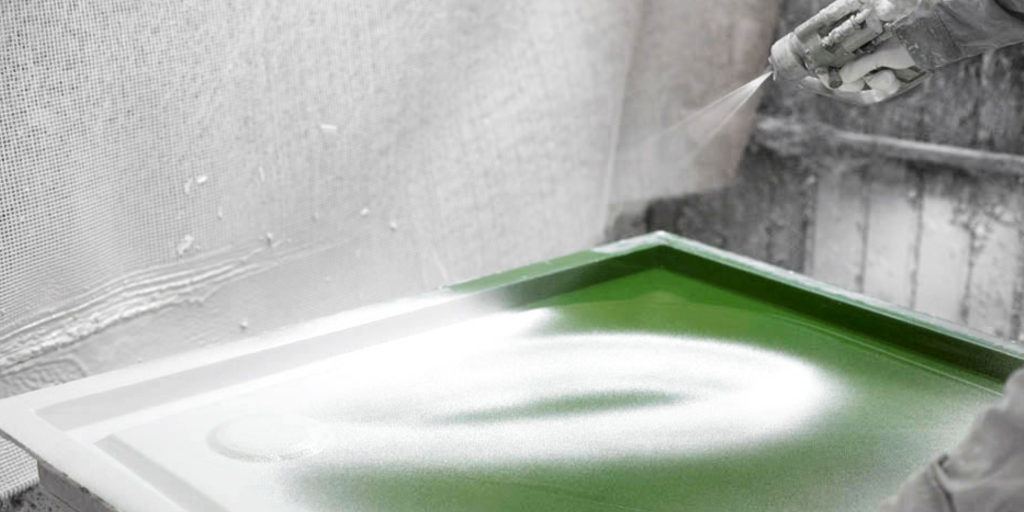

Mineral Marble

Material developed on the basis of a polymer base derived from PET recycler and of natural mineral fillers obtained from limestone and quartz rocks.

The surface of the products is covered with a layer of gel coat which is responsible for smoothness and gloss. For production we use gel coats modified with methyl methacrylate which guarantees the highest resistance to UV radiation and aggressive action of chemicals.

Benefits

- high resistance to load and impact

- resistance to abrasion and scratches

- a smooth surface that allows you to wash dirt using ordinary detergent and water

- the possibility of obtaining various surface structures (eg imitating natural wood or stone)

- the possibility of obtaining any surface colour thanks to a wide range of gel coats colour palette

Quartz

The material, which is a combination of natural quartz fillers, acrylic polymer base and additives and pigments. The share of quartz at the level >80% makes the material characterized by high hardness and abrasion resistance. The use of acrylic resin makes the material resistant to all acids and alkalies and colour change under the influence of UV.

Benefits

- surface smoothness, easy to clean

- freedom of shapes, edge finishing with r-2 radius

- designing light lines with an inclination of 89.50 ° and a wall thickness of 10 mm

- dimensional tolerance at 2 mm

- monolithic and free of air

- a multitude of colours

Acrylic - conglomerate - acrylic

Our latest achievement is the innovative technology of joining materials in a unique layered system acrylic – conglomerate – acrylic.

Benefits

- resistance to temperature changes

- resistance to chemicals and staining agents

- impact and scratch resistance

- easy cleaning

- indifference to smells

EVERHARD technology

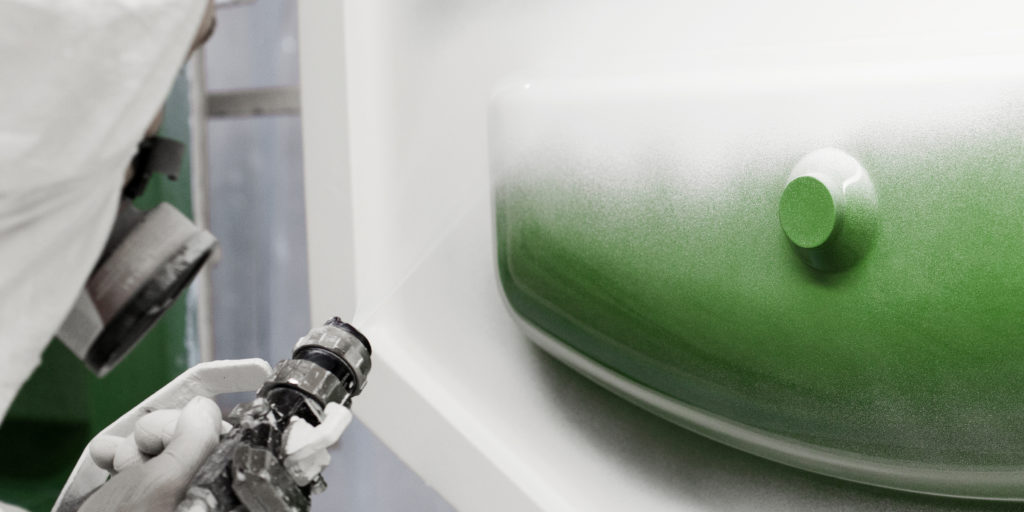

EVERHARD is a modified gel coat which, thanks to the use of modern technology, has gained high strength parameters and exceptional properties during use.

NANO SILVER technology

Innovative technology of NANO SILVER application in ceramic products which has been developed and used in our company, allows you to create any collection of sanitary products with the possibility of self-cleaning.

The EVERHARD coating used in the manufacturing of our products was created based on innovative and state-of-the-art technology in the sanitary industry. It also has a number of benefts that will be appreciated by future users.

Benefits

- 40% higher abrasion resistance

- 50% greater resistance to gloss fading

- 20% higher resistance to UV radiation

- 20% higher resistance to scratches and permanent discoloration

- prevents permanent discoloration of the material

- eliminates the accumulation of residue from water and soap

- maintains cleanliness and hygiene

- stops the growth of bacteria

EVERHARD is the perfect finish for shower trays, bathtubs and washbasins. An environmentally friendly and fully natural solution. We provide a 10-year warranty for manufacturing defects on products with the EVERHARD coating.

NANO SILVER anti-bacterial coating is a technology that spontaneously fights and prevents the growth of bacteria and fungi on the surface of the sink. During their production, a colloidal solution of silver is added to a mixture of mineral fillers and resin.

Benefits

- it never loses its properties

- no abrasion during use

- protects your and your family's health

- full microbiological protection

- it has a disinfecting effect

- technology does not change the aesthetics of products

- safe in use for a person and the environment

- higher resistance to UV radiation

The nano-particles of this metal are therefore present on the whole surface of the sink and activate always in use. Colloidal silver (pure metallic silver suspended in water) is non-toxic, colorless and odorless.

Strong technical background

The CENTRUM company is a well-known leader in the production of high quality products for kitchens and bathrooms. Strong production facilities and company efforts to manufacture high quality products are the foundation of a company built on the basis of nearly 35 years of experience. Many years of experience along with the continuous development of infrastructure translates into the competitiveness of the company in the sanitary industry.

- Machine park

- Efficient production

- The highest quality standards

- Warehouses and logistics

Modern machine park

Thanks to the highest class production lines and experience, we create products according to the customer’s needs. Automated production processes are supported by the most modern equipment:

- vacuum thermoformers

- pouring machines

- robots for composite spraying

- CNC processing center

Production capacity and high efficiency

The CENTRUM company has more than 5 production facilities enabling the company an economic production for the needs of local and foreign markets.

One of the strategic goals of the company is the increase in sales of Polish products with the highest quality and reliability on foreign markets. The production of sanitary products at the level of around 924,000 units per year includes:

- 410 000 thermo molded bathtubs and shower trays,

- 105 000 panels

- 212,000 shower trays made of mineral marble

- 144 0000 washbasins of mineral marble

- 53 000 granite sinks

The highest quality standards

The quality and performance of the products are verified by plant production control at all stages of the production process and the final control of each produced piece.

Our goal is to satisfy the client’s needs.

- efficiency, effectiveness and quality of the CENTRUM company production provides a certified quality management system according to ISO 9001: 2015 -10,

- the products are manufactured in accordance with the applicable European directives and standards,

- compliance of the designed and manufactured products with the requirements of technical standards is examined in the factory laboratory,

- after detailed quality control, our products are refined and finished manually,

- compliance with standards is additionally verified in tests commissioned to accredited units,

- additional controls as part of the final inspection - FI (Final inspection) to control the already packed product just before shipment.

Storage and transport facilities

Storage is a key element of the supply chain that enables effective service of domestic and foreign orders. We have over 8 000 m2 of storage space. New warehouses enable regular production on stock for network customers. Our activities related with warehouse logistics include, among others: warehousing, supply chain management, foiling and securing, distribution of products and maintaining the best organization of work in the hall. Our warehouse policy is meticulously thought out on every stage of order, which significantly simplifies all related processes and reduces the risk of error.

Transport

We also offer services combining storage with national and international transport. We have a modern transport fleet up to the full the disposal of our clients and timely deliveries at home and abroad.

- 14 tractor units with semi-trailers (24 tonnes)

- 5 trucks with trailers (19 tons)

- 40 passenger cars